For commercial property owners, developers, and facility managers, deploying a robust lightning protection system is not just smart, it’s essential. But installing a system is only half the job. Regular lightning protection testing and system maintenance are key to ensuring your building remains safe, compliant, and protected.

In this article, Balmore Group explains the benefits of lightning protection testing and maintenance, how often it should happen, what to look for, and why investing in lightning protection system services can save you money, risk, and stress.

Why Testing & Maintenance Matter?

A lightning protection system is more than just a lightning rod or conductor rod, it’s a network of components: air-termination rods, down conductors, grounding (earthing) systems, surge protection devices, bonds and joints. If any part fails, the whole system may be compromised. Testing and maintenance ensure:

- The system will safely intercept and conduct lightning strikes to earth without letting dangerous currents or surges travel through the structure.

- Any damage, corrosion, loose connections, or wear are identified and fixed early, before a strike reveals them.

- Compliance with British and international standards (especially BS EN 62305 in the UK) and with legal/regulatory requirements.

rafferty-steeplejacks.com - Buildings remain covered by insurance; failure to maintain or test appropriately can invalidate policies.

Key Benefits of Regular Lightning Protection Testing & Maintenance

Here are the concrete advantages when you invest in routine inspections, testing, and service of your protection system:

- Enhanced Safety for People and Property: Regular inspection of lightning conductor rods, down-conductors, joints and earthing electrodes helps identify risk factors like corrosion or damage. This reduces risk of electrical hazard, fire, or structural damage in a lightning event.

- Regulatory & Standards Compliance: Commercial lightning protection services must comply with BS EN 62305 and other standards/regulations such as the Electricity at Work Regulations 1989. Testing at defined intervals (often annually, or 11 months) ensures systems meet design and safety standards.

- Minimised Downtime & Business Continuity: By catching faults early, loose bonds, earth resistance rising, or damaged rods, you can avoid interruptions, major repairs, or failures when it’s too late. A well-maintained lightning protection system supports business operations without unexpected shutdowns.

- Cost Savings Over the Long Term: Small defects are cheaper to repair than large failures. Routine lightning protection system maintenance prolongs the lifespan of components (conductors, earth electrodes, surge protection devices), reducing replacement costs.

- Insurance & Liability Advantages: Many insurers require up-to-date inspection, testing and certification for lightning protection for buildings. Having documented lightning protection inspection or testing can help with insurance claims and reduce liability exposures.

- Protecting Electrical Systems & Equipment: Indirect effects of lightning, such as voltage surges (LEMP – lightning electromagnetic impulse), can damage sensitive wiring, electronics, servers, even if the structure avoids direct strike damage. A good system includes surge protection and ensures grounding works properly.

- Peace of Mind: Knowing that your commercial lightning protection system is tested, inspected, and maintained by accredited professionals means lower worry in storm season. It’s not just about what‐if; it’s about being prepared.

What Does Testing & Inspection Include?

When you engage professional lightning protection system services, here’s what you should expect:

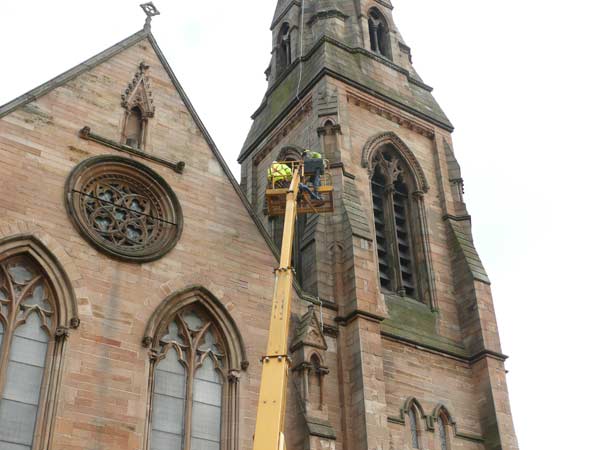

- Visual Inspection: Air terminals (lightning rods), lightning conductor rods, fastenings, joints, connectors; looking for corrosion, loose fittings, physical damage.

- Electrical Continuity & Bonding: Ensuring all conductors are continuous (no breaks), all bonds are secure, joints have low resistance.

- Grounding / Earthing Tests: Measuring resistance to earth for each electrode; ensuring the overall system’s earth termination is effective.

- Soil Resistivity: Where needed, testing soil conditions (resistivity) to understand how well grounding will work.

- Surge Protection Devices: Checking SPDs, making sure they are functioning, have not been triggered, or need replacement.

- Certification & Documentation: After testing/inspection, professionals provide reports, certification, photo documentation; keep logs of readings, tests, maintenance.

How Often Should Testing & Maintenance Be Done?

- At least once every 12 months (often interpreted as every 11 months) for most commercial lightning protection systems, in accordance with BS EN 62305.

- After any significant alteration to the structure or building (new roof works, extension, etc.).

- Following severe weather events (storms, lightning strikes, high winds) which may damage rods, connectors, or earthing.

Choosing the Right Provider

When selecting a service for commercial lightning protection services, here are things you should check:

- Accreditation & Standards Compliance: Make sure the company complies with BS EN 62305, has qualified engineers, follows relevant standards/regulations.

- Experience with Commercial Buildings: Look for providers who understand complexities of commercial installations: larger roof areas, multiple down conductors, sensitive equipment, insurance requirements.

- Transparent Pricing & Cost Estimates: Get a detailed quote for lightning rod installation (if needed), testing, maintenance, repairs. Understand commercial lightning protection system cost for both initial setup and ongoing service.

- Clear Reporting & Certification: After service, you should receive documentation proving the system is inspected, tested, and maintained correctly, useful for compliance, safety audits, insurance.

- Preventative & Proactive Maintenance Contracts: It’s often more cost-effective and safer to have an annual or multi-year maintenance schedule rather than waiting for problems to occur.

Risks of Neglecting Testing & Maintenance

Failing to keep up with inspection and maintenance can lead to:

- Increased risk of fire or structural damage in case of lightning strike.

- Damage to sensitive business equipment and data loss.

- Void insurance or rejected claims due to non-compliance.

- Legal liability if building owner fails in duty of care.

- Higher repair or replacement costs than would have been needed if small issues were found early.

Conclusion

Investing in reliable lightning protection system services, including testing, inspection, installation, and ongoing maintenance, is essential for any commercial building. Balmore Group offers end-to-end services from lightning rod installation and lightning protection installation to regular lightning protection testing and system maintenance.

Protect your building, assets, and occupants, get in touch with Balmore Group today for a professional inspection, full quotation, or maintenance contract. Ensure your system is compliant, reliable, and ready for whatever the skies bring.